Construction’s Digital Twin

– Donnie Bogle-Boesiger, Virtual Construction

Findorff’s virtual construction team specializes in an array of technology-based applications designed to revolutionize construction processes. One of the most valuable techniques they employ is the use of digital twins before construction even starts.

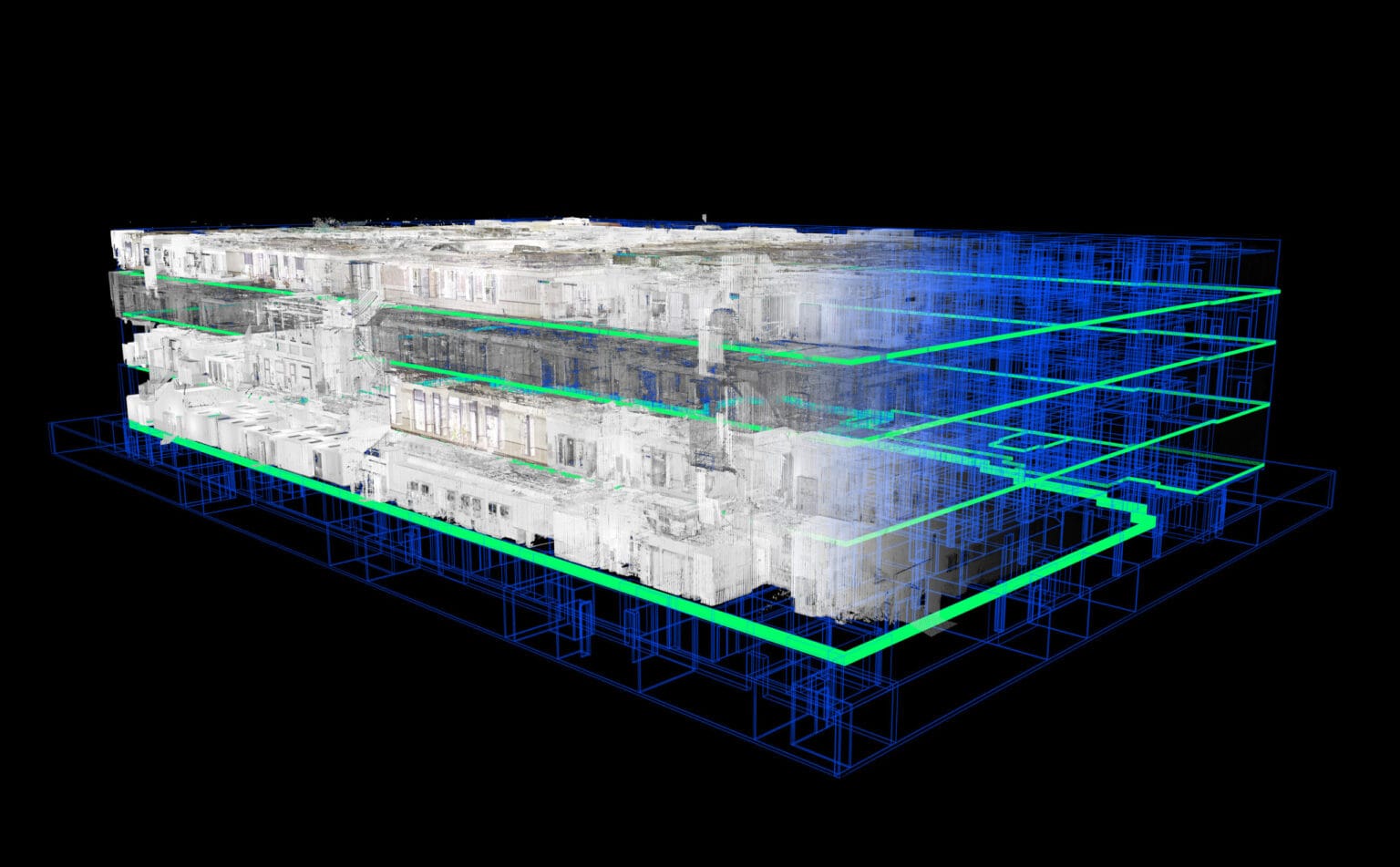

For about two decades, digital twins have been widely used in industries outside of construction. Affectionally known as “twinning,” a digital twin is a virtual model of a process, product, or service. When pairing the virtual and physical worlds together, these models allow for the analysis of data and monitoring of systems thus, creating a process that is used to alleviate problems before they even occur, prevent downtime, develop new opportunities, and incorporate simulations for future planning.Although this is not a common service in the construction industry, Findorff often utilizes digital twin technology to improve our client’s experience. By better understanding needs and enhancements to existing buildings, operations, and services, Findorff can provide a cost-effective solution to help clients understand not only what can happen in the real world, but what is happening in real-time.

Most recently, Findorff’s virtual construction team used laser scanning (reality capture technology) to provide a local historic building owner accurate as-built documentation. Amid the COVID-19 pandemic, our clients found themselves in a challenging situation where a historic 300,000 square foot building would need to undergo extensive renovations. Due to incomplete and inaccurate as-built documentation and 100 years of renovations and upgrades, the project team faced costly challenges.

Trusting as-built documentation is critical when planning for any changes to an existing building, Findorff’s virtual construction team utilized laser scanning technology to alleviate construction risk and provide a greater return on investment for our client. Laser scanning takes millions of measurements that are then translated to data points. These data points are converted into an accurate 3D model called a point cloud. This point cloud is then used to map architectural, structural, and mechanical, electrical, plumbing, and fire protection (MEPFP) elements to create a building information model (BIM). Known as scan-to-model or creating a digital twin, this process allowed Findorff to assist our client in a variety of ways, such as:

- Early collaboration with the design team to work through code-required upgrades in spaces

- Identify existing shaft locations and sizes

- Capture any renovations not recorded throughout the building’s life

By creating the model prior to the start of construction, Findorff provided the client with a high degree of confidence for more accurate budgets, fewer change orders, and fewer schedule impacts. Likewise, once the digital twin was built, the model-integrated data, like demolition/installation status, submittal documentation, and Request for Information (RFI’s) associated with specific elements of the renovation, provided the project with the below benefits:

- Expanded team communication and transparency

- Enhanced our client’s understanding of the project in real-time reporting and easy to understand visualizations

- Seamless quantification of work and understanding of productivities

- Provided clear progress of the project

Findorff’s virtual construction team is pushing the envelope on what digital twin and BIM technology can do for construction. Trying out hypothetical scenarios before putting money or resources into a new construction project proves digital twin technology and BIM-enabled workflows are much more than just visualizations – They’re a tool and resource to help our clients receive the greatest return on investment.